If the robot wants to move autonomously, it needs to have 3D perception (3D perception) function, and various sensors must be used to grasp the position of the robot in space in real time, among which LiDAR (laser radar) can provide high-precision position sensing, which has received the most attention from the industry. In addition, the robot also needs to be driven by motors to perform precise movements of itself or its limbs. This article will introduce you to the development of LiDAR technology and the LiDAR and motor drive solutions introduced by ROHM.

Lidar drives innovation in new services

AI robots in the near future refer to robots that can judge their own position and recognize their own actions in three-dimensional space by adding 3D perception functions to autonomous mobile robots (AMRs), so as to achieve advanced autonomous movement and various motion control robots. AMR to carry out a variety of motion control, not only need to confirm its own position, but also need to conduct real-time 3D perception data processing (such as the classification of surrounding objects, object tracking, etc.), so the use of LiDAR and camera technology architecture has become the mainstream of the industry.

With the increasing amount of real-time 3D perception data, the construction of deep learning models has become the current trend of technology development. Since the learning environment of deep learning models is usually under ideal conditions, state inference can be made accurately. However, in the actual working environment of the robot, it is inevitable to face the problems of incomplete sensor information and complex movement control.

The LiDAR module used by the robot has high resolution requirements for LD (laser diode), so the performance of the LD used mainly has the following two requirements, first, the size of the light source should be as small as possible, and the second is the divergence Angle of the beam should be as small as possible. In general, the light emitted from a semiconductor laser diode has a certain divergence Angle, so it is necessary to use a collimating lens to change the light into parallel light (Figure 1).

Figure 1: Influence of light source size on spot size

However, collimating lenses do not completely convert the light emitted by semiconductor laser diodes into parallel light. Generally, the beam emitted from the lens has a certain divergence Angle (θ), which is determined by the relationship between the size of the light source and the focal length of the lens (formula 1).

Formula 1: θ ~ d/f

(d is the size of the light source, f is the focal length of the lens)

To achieve high resolution, it is necessary to further reduce the divergence of the beam from the lens (θ in Figure 1). Regarding the LD's light source size, because the divergence Angle (θ) of the beam coming from the lens is proportional to the LD's light source size (d), so if d is reduced by 50%, θ will also be reduced by 50%. As for the divergence Angle of the beam, it can be seen from formula 1 that the longer the focal length, the smaller the divergence Angle of the beam emitted from the lens, so it is best to choose LD with small divergence Angle.

Figure 2 is a schematic representation of the focal length difference when the LD beam divergence Angle is 20deg and 25deg. In the case of the same lens diameter, if you use a LD with a beam divergence Angle of 20deg, you can choose a lens with a focal length of about 25%. In this way, the divergence Angle (θ) of the beam emitted from the lens can also be reduced by about 20%, and the spot size can also be reduced by 20%.

Figure 2: Relationship between beam divergence Angle and focal length (comparison at 20deg and 25deg)

AI robots that can work autonomously

High-precision LiDAR solutions

For these practical operating environment problems, ROHM introduced LiDAR solutions consisting of laser diodes with excellent edge detection capabilities and high-precision point cloud data output, GaN HEMTs that can drive laser diodes at high speeds, and gate driver ics to drive GaN HEMTs. An AI robot that can work autonomously through an end-to-end model that can acquire stable 3D perception data.

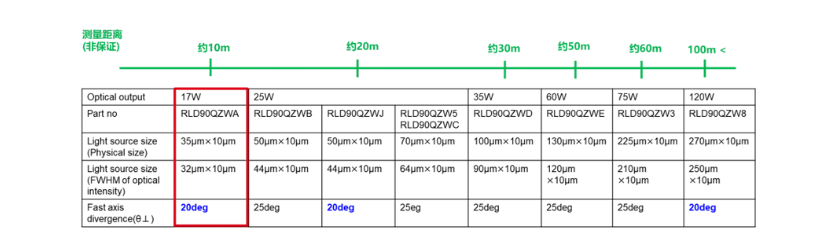

ROHM's extensive portfolio of semiconductor laser diodes for LiDAR includes products such as the RLD90QZWA for the industry's ultra-small light source size (35µm ×10µm) and the high-power RLD90QZW8 for 270µm ×10µm (Table 1).

Table 1: ROHM LD product lineup for LiDAR

When the product is used in a robot application, the key is the accurate perception of the surrounding environment of about 10 to 20m. For robot applications that require close distance accurate ranging, RLD90QZWA, which will be put into mass production in 2022, is recommended, and the light source size of this product reaches the industry's ultra-small level, only 35μm×10μm size, and the beam divergence Angle (fast axis direction) is 20deg. Compared with the previous product RLD90QZW5 (light source size 70μm×10μm, θ⊥=25deg), the divergence Angle of the lens outgoing beam is reduced by 60%. With this RLD90QZWA, you can not only choose a lens with a longer focal length, but also obtain more accurate point cloud data.

GaN HEMT for faster development

Laser drive reference design

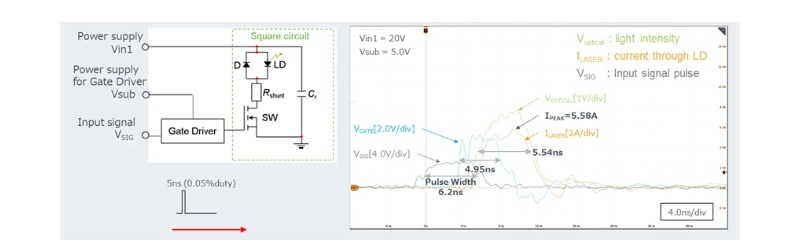

Usually, LiDAR adopts ToF (Time of Flight) ranging method. The ToF method is a distance measurement method that calculates the distance by measuring the time it takes for the light emitted from the light source to return to the receiver after the reflection of the target. If the pulse width is too large, the light pulse signal received by the receiver is easy to aliasing together, so that it is difficult to distinguish between more than two objects close to each other. Therefore, to improve the resolution, it is necessary to reduce the pulse width. In order to build a system capable of obtaining more accurate point cloud data through narrow pulse signals, ROHM has developed a reference design "REFLD002" that combines GaN HEMT (EcoGaN™), the key in laser diode drivers, with the single-channel high-speed gate driver IC for GaN HEMT drivers. And has published the relevant design information on the ROHM official website.

Figure 3: GaN HEMT Laser Drive reference design "REFLD002"

In order to fully exploit the high-speed driving characteristics of GaN HEMTs, high-speed gate drivers must be used for driving. The single channel high speed gate driver IC "BD2311NVX-LB (Industrial equipment) /-C (Vehicle)" developed by ROHM for GaN HEMT drives has begun to be sampled. The drive mode of this product can reduce overshoot by about 10% while maintaining a high conversion rate, which is ahead of similar products in the industry. In addition, while a regular GaN HEMT has a gate-to-source voltage of 6V, ROHM's EcoGaN™ achieves 8V. Based on these product advantages, users will no longer have to worry about the damage caused by overshoot when driving circuit switches, and circuit design will become easier.

Figure 4: Drive waveform of laser diode "RLD90QZWA"

In addition, ROHM official website also published a free simulation tool "ROHM Solution Simulator", and equipped with the corresponding simulation circuit, users can use the simulation tool to easily confirm the waveform changes under different circuit constants, which is of great help for the early design research.

In addition, ROHM's official website also discloses the application guide of the product monomer, simulation models (SPICE models, Ray data) and PCB library data. By directly using the reference design, and effectively using the circuit simulation and related product data of the reference design, users can significantly reduce the design and evaluation hours, and greatly shorten the cycle of related products into the market.

Small and efficient motor drive solutions

Robot applications are closely related to motor drive, and the motor drive solution launched by ROHM includes the indispensable MOSFETs in the motor drive by the wheel train related to the autonomous movement of the robot and the controller related to the various motion control of the robot, as well as the gate driver IC used to drive the MOSFETs, which has the characteristics of small and efficient.

For battery-driven autonomous mobile robots, the mainstream power supply scheme is DC24 ~ 72V power supply, while for industrial robots, DC48V power supply is mainly used. With the development of technologies such as AI, sensing (image recognition) and drive capabilities, the functions of robots are constantly upgraded, and correspondingly, more power needs to be consumed. In this context, the problem of power conversion technology has become increasingly prominent and has become an urgent issue to be solved, and the power conversion efficiency in the field of AI robotics has also become a crucial factor.

ROHM combines the 100V high and low side gate driver IC "BD2320UEFJ-LA", which can drive external Nch MOSFETs, motor drives ideal for DC48V applications, with Nch, which uses copper clip structure, compact package and low power loss The combined solution of MOSFET "RS6xxxxBx/RH6xxxxBx series" reduces switching loss and on-off loss, which is very helpful to improve the efficiency of application products.

Figure 5: Schematic diagram of ROHM's gate driver IC and Nch MOSFET product package

For example, when comparing the power efficiency on the power evaluation board used in industrial equipment, the power efficiency of the RS6xxxxBx/RH6xxxxBx series is as high as 95.01% at peak time in the output voltage range during steady state operation.

Figure 6: Efficiency comparison of RS6xxxxBx/RH6xxxxBx series with common products

Conclusion

Robots with 3D sensing LiDAR solutions, combined with AI technology, will take robot applications to a new generation. ROHM introduces the ROHM LiDAR solution for advanced autonomous mobility and various motion control modules in the field of AI robotics, by combining a laser diode with the industry's ultra-small light source size and a GaN HEMT (EcoGaN™) that drives laser diodes at high speeds. Combined with the gate driver ics used to drive GaN HEMTs, they help build systems that can obtain more accurate point cloud data.

In addition, ROHM has introduced motor drive solutions that enable applications to further improve efficiency by combining high-low gate driver ics, which are ideal for motor drives, with Nch MOSFETs with copper clip construction, compact package and low power loss. Not only that, ROHM also disclosed the relevant reference design and free simulation tool "ROHM Solution Simulator" on the official website, the effective use of these resources can help users reduce the design and evaluation hours, greatly shorten the cycle of related products into the market, will be the ideal choice for related robot applications.

Heisener Electronic is a famous international One Stop Purchasing Service Provider of Electronic Components. Based on the concept of Customer-orientation and Innovation, a good process control system, professional management team, advanced inventory management technology, we can provide one-stop electronic component supporting services that Heisener is the preferred partner for all the enterprises and research institutions.